Advanced Smart Automatic Edge Bander

Product Details:

- Type Advanced Smart Automatic Edge Bander

- Material High-Grade Steel, ABS Plastic

- Capacity Up to 30 meters/minute

- Computerized Yes

- Automatic Grade Fully Automatic

- Voltage 380V

- Frequency (MHz) 50-60 MHz

- Click to view more

X

Advanced Smart Automatic Edge Bander Product Specifications

- Up to 30 meters/minute

- Yes

- 120 x 70 mm

- High-Grade Steel, ABS Plastic

- 380V

- 900 kg

- 0.4 - 3 mm

- 450 mm

- Large Industrial

- 4200 x 900 x 1700 mm

- Advanced Smart Automatic Edge Bander

- Fully Automatic

- 80 mm

- 50-60 MHz

Product Description

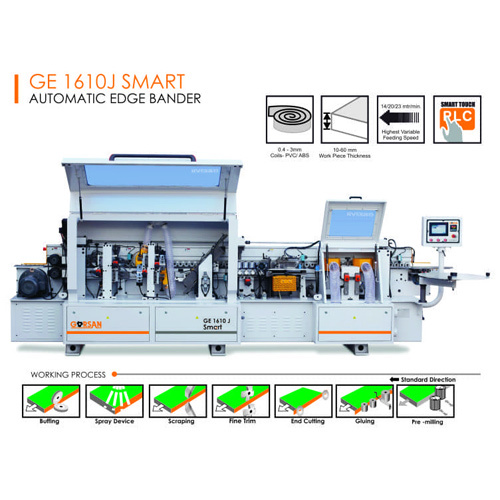

Experience the fresh innovation of the Advanced Smart Automatic Edge Bander, now offered at a special rate! Dominating the market with in-demand automation, this stellar machine handles edge banding for panels as small as 60mm in width and 10mm in thickness. Its inestimable glue pot capacity (2.5 kg) and adjustable feeding speed (13-23 m/min) ensure unwavering performance. With touchscreen control, high-grade steel and ABS construction, and fully automatic, computerized operation, its the perfect solution for manufacturers, exporters, and suppliers seeking efficiency, safety, and precision in industrial woodworking.

Unmatched Advantages and Applications of the Edge Bander

The Advanced Smart Automatic Edge Bander offers significant advantages, including fully automatic operation, emergency stop safety features, and a user-friendly touchscreen interface. With workpiece thickness adjustment, pre-milling, gluing, end cutting, trimming, scraping, and buffing, it supports various applications, from furniture production to cabinetry. Its robust structure, high feeding speed, and compatibility with multiple edge band thicknesses make it a dominant choice for woodworking industries, factories, and workshops seeking efficiency and top-quality finishes.

Sample Policy, Certifications, and Shipping Details

Samples of the Advanced Smart Automatic Edge Bander can be shipped on request, ensuring customers experience its quality firsthand before order arrival. The machine is delivered with necessary certifications for technical and safety standards compliance. Efficient delivery is organized via major FOB ports in India, guaranteeing timely arrival and smooth logistics. Our team handles export documentation and inspection, streamlining the process for both Indian and international clients, so you receive your stellar equipment ready for installation.

Unmatched Advantages and Applications of the Edge Bander

The Advanced Smart Automatic Edge Bander offers significant advantages, including fully automatic operation, emergency stop safety features, and a user-friendly touchscreen interface. With workpiece thickness adjustment, pre-milling, gluing, end cutting, trimming, scraping, and buffing, it supports various applications, from furniture production to cabinetry. Its robust structure, high feeding speed, and compatibility with multiple edge band thicknesses make it a dominant choice for woodworking industries, factories, and workshops seeking efficiency and top-quality finishes.

Sample Policy, Certifications, and Shipping Details

Samples of the Advanced Smart Automatic Edge Bander can be shipped on request, ensuring customers experience its quality firsthand before order arrival. The machine is delivered with necessary certifications for technical and safety standards compliance. Efficient delivery is organized via major FOB ports in India, guaranteeing timely arrival and smooth logistics. Our team handles export documentation and inspection, streamlining the process for both Indian and international clients, so you receive your stellar equipment ready for installation.

Specification

|

Auto Edge Bander |

GE 1610 J SMART |

|

WORK PIES THIKNESS ADUGSTMENT |

ELECTRICLE |

|

MIN. WORK PIECE WIDTH |

60MM |

|

MAX. WORK PIECE LENGTH |

120MM |

|

MIN. WORK PIECE THICKNES |

10MM |

|

MAX. WORK PIECE THICKNESS |

60MM |

|

PVC EDGE BAND TAP THICKNESS |

0.4 TO 3MM |

|

CONVEYER FEED SPEED |

14MTR / 20MTR / 23MTR /MIN |

|

GLUE TANK CAPACITY |

2 KG |

|

PRE - MILLING MOTOR POWER |

2HP X 2 |

|

END CUTTING MOTOR POWER |

1HP X 2 |

|

FINE TRIMMING MOTOR POWER |

1 HP X 2 |

|

BUFFING MOTOR POWER |

0.5HP X 2 |

|

INSTALLED POWER |

17HP |

|

OVERALL SIZE |

4470 X 900 X 1600MM (LXWXH) |

|

WITH |

PRE-MILLING GLUING, END CUTTINGTOP & BOTTOM TRIMMING SCRAPING AND BUFFING |

FAQs of Advanced Smart Automatic Edge Bander:

Q: How does the touchscreen control panel enhance the usage of the edge bander?

A: The touchscreen control panel streamlines operation, allowing for simple adjustments, quick setting changes, and real-time monitoring, resulting in efficient and precise edge banding.Q: What is the process for on-site installation and training?

A: Upon delivery, our technical team visits your facility for on-site installation and comprehensive training, ensuring your staff understands all operational and safety protocols.Q: Where can the Advanced Smart Automatic Edge Bander be effectively applied?

A: This edge bander is ideal for furniture manufacturers, cabinetry workshops, large-scale woodworking industries, and factories that demand reliable and high-speed edge processing.Q: What are the main benefits of its fully automatic, computerized operation?

A: Fully automatic, computerized control eliminates manual errors, improves productivity, and delivers consistent, high-quality output while reducing labor costs and downtime.Q: How is delivery and shipping managed for international orders?

A: Shipments are coordinated through major Indian FOB ports, with professional logistics support to ensure safe arrival and timely delivery at your specified location.Q: When can customers expect to receive their product samples?

A: Sample shipments are processed promptly after request, with estimated arrival timelines communicated clearly based on destination and selected shipping options.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free