Electrical PRIME Automatic Edge Bander

Product Details:

- Type Edge Bander

- Material Metal

- Capacity High Production Rate

- Computerized Yes

- Automatic Grade Automatic

- Voltage 380 V

- Frequency (MHz) 50 Hz

- Click to view more

X

Electrical PRIME Automatic Edge Bander Product Specifications

- Yes

- High Production Rate

- 1510 mm

- Standard

- 380 V

- Metal

- 0.43 mm

- 3700 mm x 900 mm x 1560 mm

- 50 Hz

- Edge Bander

- 180 mm x 85 mm

- Automatic

- 30 mm

- 650 kg

- 1220 m/min

- 0.6 MPa

- 1.8 kW

- Woodworking Panel Edgebanding

- 540C

- 900 mm

- 7.5 kW

- 1060 mm

- 2.5 kg

- 1265 mm

- 80 dB

- PLC Touch Screen

Product Description

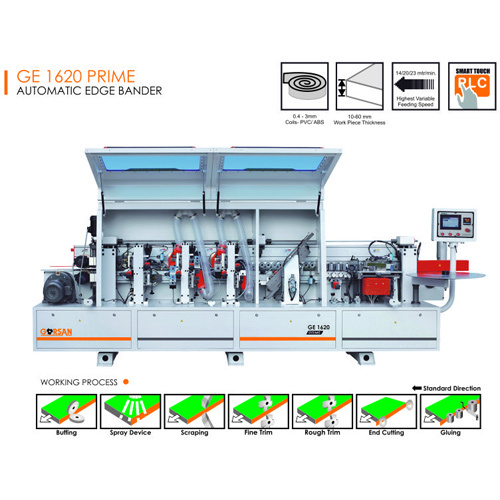

The Electrical PRIME Automatic Edge Bander unlocks sensational control and majestic efficiency in woodworking. Featuring a high feeding speed of 1220 m/min, it optimizes productivity with reduced downtime and dependable glue pot volume of 2.5 kg. Its PLC touch screen ensures smooth automated operation, while reduced noise levels (80 dB) create a comfortable work environment. The system is featured with adjustable panel thickness (1060 mm) and preheating plate, offering optimum results for diverse edgebanding applications. Unleash extraordinary quality with every use and experience the convenience of a robust, computerized solution built for Indias manufacturing demands.

Standout Features and Versatile Applications

The Electrical PRIME Automatic Edge Bander is packed with extra features like a PLC touch screen, advanced preheating plate, and optimum motorized functions for gluing, trimming, scraping, anti-adhesive spraying, and buffing. Special features include rapid adjustment for different panel sizes and a sensational capacity for high production rates. This majestic machine isnt just for routine edgebandingit handles a variety of panel processing tasks efficiently for furniture, cabinetry, and decorative wood surfaces.

Delivery, Packaging, and Sample Policy Details

Upon confirmation of the proposal amount, the Electrical PRIME Automatic Edge Bander is meticulously packaged for secure freight delivery. Customers can expect a prompt arrivaltypically within a standard lead time coordinated with the distributor. Comprehensive packaging safeguards the unit from transit damage. Sample policies vary but can be arranged upon request, offering prospective buyers a practical insight into the machines efficiency and features before a full-scale investment.

Standout Features and Versatile Applications

The Electrical PRIME Automatic Edge Bander is packed with extra features like a PLC touch screen, advanced preheating plate, and optimum motorized functions for gluing, trimming, scraping, anti-adhesive spraying, and buffing. Special features include rapid adjustment for different panel sizes and a sensational capacity for high production rates. This majestic machine isnt just for routine edgebandingit handles a variety of panel processing tasks efficiently for furniture, cabinetry, and decorative wood surfaces.

Delivery, Packaging, and Sample Policy Details

Upon confirmation of the proposal amount, the Electrical PRIME Automatic Edge Bander is meticulously packaged for secure freight delivery. Customers can expect a prompt arrivaltypically within a standard lead time coordinated with the distributor. Comprehensive packaging safeguards the unit from transit damage. Sample policies vary but can be arranged upon request, offering prospective buyers a practical insight into the machines efficiency and features before a full-scale investment.

Specification

|

Auto Edge Bander |

GE 1620 PRIME |

|

WORK PIES THIKNESS ADUGSTMENT |

ELECTRICAL |

|

MIN. WORK PIECE WIDTH |

60MM |

|

MAX. WORK PIECE LENGTH |

120MM |

|

MIN. WORK PIECE THICKNES |

10MM |

|

MAX. WORK PIECE THICKNESS |

60MM |

|

PVC EDGE BAND TAP THICKNESS |

0.4 TO 3MM |

|

CONVEYER FEED SPEED |

14MTR / 20MTR / 23MTR /MIN |

|

GLUE TANK CAPACITY |

2 KG |

|

END CUTTING MOTOR POWER |

1HP X 2 |

|

ROUGH TRIMMING MOTOR POWER |

1 HP X2 |

|

FINE TRIMMING MOTOR POWER |

1 HP X 2 |

|

BUFFING MOTOR POWER |

0.5HP X 2 |

|

INSTALLED POWER |

13 HP |

|

OVERALL SIZE |

4470X 900 X 1600MM (LXWXH) |

|

WITH |

GLUING, END TRIMMING, ROUGH TRIMMING, TOP & BOTTOM TRIMMING,SCRAPING ANTY ADHISIVE SPREY AND BUFFING |

FAQs of Electrical PRIME Automatic Edge Bander:

Q: How does the PLC touch screen benefit the operation of the Edge Bander?

A: The integrated PLC touch screen provides intuitive control, reduces manual intervention, and allows for precise adjustment of all functions, ensuring optimum efficiency and effortless operation.Q: What is the process for adjusting panel thickness on this machine?

A: Panel thickness adjustment is electrical and user-friendly, supporting workpieces from 10 mm up to 60 mm, allowing for seamless transitions between different production requirements.Q: When can customers expect delivery after placing an order?

A: After finalizing the proposal amount, delivery is arranged promptly, with shipping timelines transparently communicated. Arrival depends on location and freight logistics, but prompt dispatch is prioritized.Q: Where is the Electrical PRIME Automatic Edge Bander suitable for use?

A: This machine is ideal for woodworking workshops, furniture manufacturing, cabinetry operations, and panel processing factories seeking reliable, high-volume edgebanding solutions.Q: What special features help reduce noise and energy consumption?

A: The Edge Bander is engineered for reduced noise (80 dB) and features high-efficiency motors, ensuring energy use is minimized without sacrificing performance.Q: How does the automatic grade enhance productivity?

A: Its automatic grade, including features like motorized trimming and buffing, dramatically speeds up the edgebanding process for optimum production output with less manual oversight.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free