GE - 1621 J PRIME Automatic Edge Bander

Product Details:

- Type Automatic Edge Bander

- Material Steel Body

- Capacity 200 Pieces/8 Hours

- Computerized Yes

- Automatic Grade Automatic

- Voltage 380V

- Frequency (MHz) 50 Hz

- Click to view more

GE - 1621 J PRIME Automatic Edge Bander Product Specifications

- Steel Body

- 1621 mm

- 35 mm

- 380V

- 200 Pieces/8 Hours

- 4200 x 950 x 1621 mm

- Yes

- Automatic Edge Bander

- 0.4 3 mm

- 650 kg

- Automatic

- 50 Hz

- 950 mm

- 60 mm

- Integrated with Teflon Coated Pot

- 85 dB

- PVC, ABS, Wood Veneer, Melamine

- 0.6 MPa

- 12-20 m/min

- Double-Sided Buffers

- Fan Assisted

- 10-60 mm

- 80 mm

- PLC Touch Screen

- 0.4-3 mm

- 930 mm

- 150 mm

- High-Precision Cutters

- 7.5 kW

GE - 1621 J PRIME Automatic Edge Bander Trade Information

- AHMEDABAD

- Cash Advance (CA), Cash in Advance (CID)

- 10 Per Month

- 15 Days

- As Per Client's Requirment.

- Asia

- All India

- ISO,

Product Description

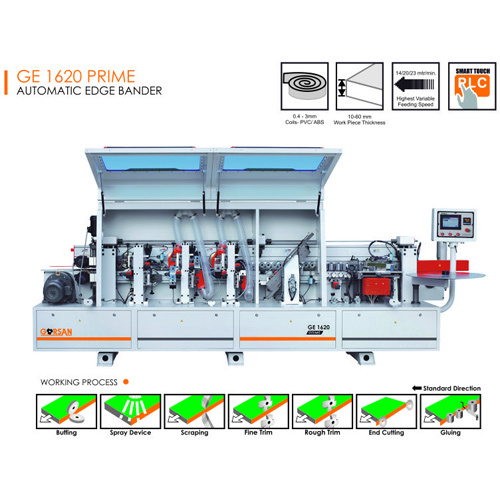

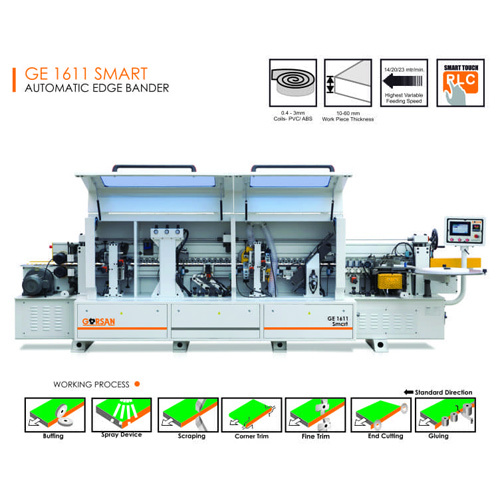

Specification

|

Auto Edge Bander |

GE 1621 J PRIME |

|

WORK PIES THIKNESS ADUGSTMENT |

ELECTRICLE |

|

MIN. WORK PIECE WIDTH |

60MM |

|

MAX. WORK PIECE LENGTH |

120MM |

|

MIN. WORK PIECE THICKNES |

10MM |

|

MAX. WORK PIECE THICKNESS |

60MM |

|

PVC EDGE BAND TAP THICKNESS |

0.4 TO 3MM |

|

CONVEYER FEED SPEED |

14MTR / 20MTR / 23MTR /MIN |

|

GLUE TANK CAPACITY |

2 KG |

|

PRE-MILLING MOTOR POWER |

2 HP X 2 |

|

END CUTTING MOTOR POWER |

1HP X 2 |

|

ROUGH TRIMMING MOTOR POWER |

1 HP X 2 |

|

FINE TRIMMING MOTOR POWER |

1 HP X 2 |

|

CORNER TRIM MOTOR POWER |

1HP X 2 |

|

BUFFING MOTOR POWER |

0.5HP X 2 |

|

INSTALLED POWER |

22 HP |

|

OVERALL SIZE |

6600X 900 X 1600MM (LXWXH) |

|

WITH |

PRE-MILLING,GLUING, END TRIMMING, ROUGH TRIMMING,FINE TRIMMING,CORNER ROUNDING, TOP & BOTTOM TRIMMING,CORNER ROUNDING,SCRAPING ANTY ADHISIVE SPREY AND BUFFING |

Advanced Gluing and Edge Banding Technology

The GE - 1621 J PRIME features a Teflon-coated gluing pot, ensuring smooth, continuous adhesive application and easy cleaning. With its automated controls and efficient feeding speeds, this machine meets the demands of high-volume production environments while maintaining consistent, high-quality edge finishing results.

Precision and Versatility for Diverse Materials

Designed to accommodate various materials such as PVC, ABS, wood veneer, and melamine, the edge bander suits a wide spectrum of woodworking projects. Its adjustable settings allow flexibility in panel and tape thickness, supporting custom fabrication and a variety of design requirements.

Intuitive Operation and Robust Construction

A PLC touch screen control system simplifies operation and monitoring, making production adjustments straightforward. Combined with a solid steel body and advanced trimming and buffing units, this machine delivers durability, operator safety, and professional-level finishing.

FAQs of GE - 1621 J PRIME Automatic Edge Bander:

Q: How does the GE - 1621 J PRIME Automatic Edge Bander enhance edge finishing quality?

A: The GE - 1621 J PRIME utilizes Teflon-coated gluing technology for even adhesive distribution and high-precision cutters paired with double-sided buffers to achieve seamless, smooth edges on various panel materials, ensuring a professional finish on every workpiece.Q: What types of edge banding materials can be used with this machine?

A: This model is compatible with PVC, ABS, wood veneer, and melamine edge tapes ranging from 0.4 mm to 3 mm in thickness, providing versatility for different woodworking requirements.Q: When should I use the GE - 1621 J PRIME for my manufacturing process?

A: This edge bander is ideal for continuous, high-capacity operationssuch as cabinet, furniture, or interior fixture manufacturingwhere consistent quality and rapid panel processing (up to 200 pieces in 8 hours) are essential.Q: Where can this machine be installed within my production facility?

A: With dimensions of 4200 x 950 x 1621 mm, the GE - 1621 J PRIME is best suited for placement in woodworking factories or large workshops with access to 380V power; ensure a dust-free, ventilated, and level area to optimize performance and ease of operation.Q: What is the operation process of the GE - 1621 J PRIME Automatic Edge Bander?

A: Operators set up the desired panel size and edge tape parameters using the PLC touch screen. Panels are then fed into the machine, which applies adhesive, trims, and buffs the edges automatically. The systems fan-assisted cooling ensures adhesives set quickly for immediate handling.Q: How does this machine benefit production efficiency?

A: Automating the edge banding process increases output (up to 200 panels per eight-hour shift) and reduces manual labor, while consistent glue application and trimming contribute to fewer errors and minimal rework, ultimately saving time and reducing costs.Q: What maintenance is required for optimal performance?

A: Regular cleaning of the Teflon-coated pot, inspection of cutters and buffers, and monitoring of air pressure and cooling systems are recommended. Professional servicing as outlined by the distributor or manufacturer helps ensure long-term reliability and performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+