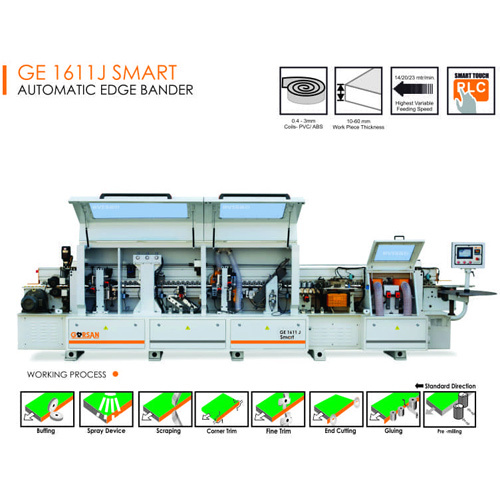

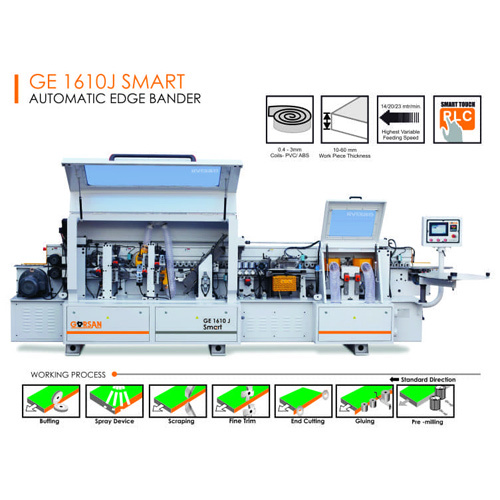

GE 1611 J SMART SMART Automatic Edge Bander

Product Details:

- Type Edge Bander

- Material Steel Body & Powder Coated Structure

- Capacity Up to 60 m/min

- Computerized Smart

- Automatic Grade Automatic

- Voltage 380 V

- Frequency (MHz) 50 Hz

- Click to view more

X

GE 1611 J SMART SMART Automatic Edge Bander Product Specifications

- 600 mm

- Automatic

- 4300 mm x 1000 mm x 1700 mm

- Medium Industrial

- 0.4 3 mm

- Smart

- Steel Body & Powder Coated Structure

- 80 mm

- 850 kg

- Up to 60 m/min

- 380 V

- 1100 mm

- 50 Hz

- Edge Bander

- Automatic

- 7 kW

- <75 dB

- 0.43 mm PVC/ABS

- Yes

- 0.18 kW x 2 Units

- 1.5 kW

- Touchscreen Smart Controller

- Pre-milling, Gluing, Pressing, End cutting, Fine trimming, Scraping, Buffing & Corner Rounding

- 1060 mm

- 2 kg

- 80 mm

- 1023 m/min

- Dual 0.35 kW Each

- 120 mm

- Emergency Stop Button

- PVC, ABS, Veneer, Melamine

Product Description

Unlock elite woodworking capability with the GE 1611 J SMART SMART Automatic Edge Bander. Experience exceptional performance with sublime precision, featuring a 2 kg glue pot, feeding speeds up to 23 m/min, and edge tape thicknesses of 0.43 mm for PVC/ABS. Its opulent touchscreen Smart Controller, automated corner rounding, and robust steel body redefine efficiency and operational excellence. Buy online to embrace this opulent solution for fine, durable finishes in commercial or industrial furniture production, ensuring every edge is finished with unrivaled finesse.

Versatile Applications for Industrial Excellence

The GE 1611 J SMART SMART Automatic Edge Bander is suitable for a wide spectrum of wood panel processing, making it ideal for furniture manufacturing, cabinetry, and interior industry applications. Its adaptability supports various edge materials including PVC, ABS, veneer, and melamine. Designed for medium industrial environments, it excels in handling diverse workpiece sizesdelivering consistent results for both small batch work and large-scale operations. This makes it the preferred choice for precise edge finishing in competitive manufacturing sectors.

Export Markets, Supply, and Competitive Sale Pricing

As a trusted exporter, manufacturer, distributor, supplier, and trader, the GE 1611 J SMART SMART Automatic Edge Bander is dispatched to leading markets across India and globally. With substantial supply ability to meet volume demands, each machine is carefully packaged for safe transport. Sale price and asking price are tailored for business competitiveness, ensuring exceptional value for quality. Efficient processing and timely dispatching enhance customer experience, making it an optimal investment for commercial enterprises.

Versatile Applications for Industrial Excellence

The GE 1611 J SMART SMART Automatic Edge Bander is suitable for a wide spectrum of wood panel processing, making it ideal for furniture manufacturing, cabinetry, and interior industry applications. Its adaptability supports various edge materials including PVC, ABS, veneer, and melamine. Designed for medium industrial environments, it excels in handling diverse workpiece sizesdelivering consistent results for both small batch work and large-scale operations. This makes it the preferred choice for precise edge finishing in competitive manufacturing sectors.

Export Markets, Supply, and Competitive Sale Pricing

As a trusted exporter, manufacturer, distributor, supplier, and trader, the GE 1611 J SMART SMART Automatic Edge Bander is dispatched to leading markets across India and globally. With substantial supply ability to meet volume demands, each machine is carefully packaged for safe transport. Sale price and asking price are tailored for business competitiveness, ensuring exceptional value for quality. Efficient processing and timely dispatching enhance customer experience, making it an optimal investment for commercial enterprises.

Specification

|

Auto Edge Bander |

GE 1611 J SMART |

|

WORK PIES THIKNESS ADUGSTMENT |

ELECTRICAL |

|

MIN. WORK PIECE WIDTH |

60MM |

|

MAX. WORK PIECE LENGTH |

120MM |

|

MIN. WORK PIECE THICKNES |

10MM |

|

MAX. WORK PIECE THICKNESS |

60MM |

|

PVC EDGE BAND TAP THICKNESS |

0.4 TO 3MM |

|

CONVEYER FEED SPEED |

14MTR / 20MTR / 23MTR /MIN |

|

GLUE TANK CAPACITY |

2 KG |

|

PRE - MILLING MOTOR POWER |

2HP X 2 |

|

END CUTTING MOTOR POWER |

1HP X 2 |

|

FINE TRIMMING MOTOR POWER |

1 HP X 2 |

|

BUFFING MOTOR POWER |

0.5HP X 2 |

|

CORNER TRIM MOTOR POWER |

1HP X 2 |

|

INSTALLED POWER |

19HP |

|

OVERALL SIZE |

6130 X 900 X 1600MM (LXWXH) |

|

WITH |

PRE-MILLING, GLUING, END CUTTING TOP & BOTTOM TRIMMING, CORNER ROUNDING, SCRAPING, ANTI ADHESIVE SPRAY AND BUFFING |

FAQs of GE 1611 J SMART SMART Automatic Edge Bander:

Q: How does the GE 1611 J SMART SMART Automatic Edge Bander optimize productivity in furniture manufacturing?

A: Its automatic functions like pre-milling, gluing, pressing, end cutting, fine trimming, and buffing streamline production, increasing throughput and reducing manual effort, making it ideal for high-volume woodworking.Q: What types of edge tapes and materials can the machine handle?

A: The machine works seamlessly with PVC, ABS, veneer, and melamine tapes, allowing for versatile usage across different furniture and panel products.Q: Where can the GE 1611 J SMART be installed, and what are its space requirements?

A: Its designed for medium industrial settings with a footprint of 4300 mm x 1000 mm x 1700 mm, making it suitable for factories and advanced workshops requiring reliable edge banding.Q: When should the glue pot be refilled, and what is its capacity?

A: The edge bander features a 2 kg glue pot, suitable for extended runs; refills are needed based on usage rates and production volumes, keeping downtime to a minimum.Q: What are the key safety features built into the edge bander?

A: For operator protection, it incorporates an emergency stop button and operates at a noise level below 75 dB, supporting a safe and comfortable workspace.Q: How does the touchscreen Smart Controller improve user operation?

A: The intuitive touchscreen interface enables easy adjustments, process supervision, and parameter setting, resulting in efficient, accurate, and user-friendly machine control.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free